S. Himmelstein and Company has been focused on designing, making and servicing precision torque transducers and signal conditioners since 1960. We offer the most accurate torque transducer products with the highest torque overload and electrical overrange and reliability available. Furthermore, these torque transducers and state of the art signal conditioners provide Himmelstein users with the fastest, most accurate dynamic response with the highest safety margins. Reaction and rotating sensors are offered in many styles including bearingless, shaft, flanged, splined, wheel, pulley, C-Face and hollow types. Performance is proven and documented in our accredited ISO/IEC 17025:2017 Calibration Laboratory.

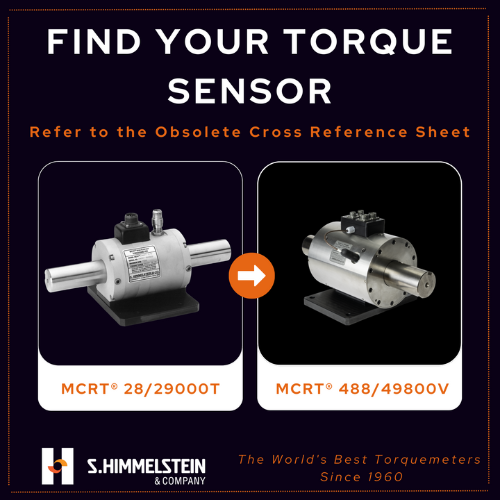

Having trouble finding an exact match to your existing torquemeter? View this updated form.

We are happy to announce the Wayne Fregeau has joined our team as our new Sales Manager!

Browse our popular models below in shaft, flanged, rotating and reaction sensors.

Himmelstein offers the largest selection of torque transducers, output signals, overload ratings, accuracy grades and mechanical styles, so you’re sure to find the ideal torque transducer to meet the needs of your application. All Himmelstein torque transducers and systems are calibrated CW and CCW to their full-scale capacity in our ISO/IEC 17025:2017 accredited laboratory (NVLAP Lab Code 200487-0). With Himmelstein, you enjoy the benefits of our long experience along with the most stringent quality control standards.

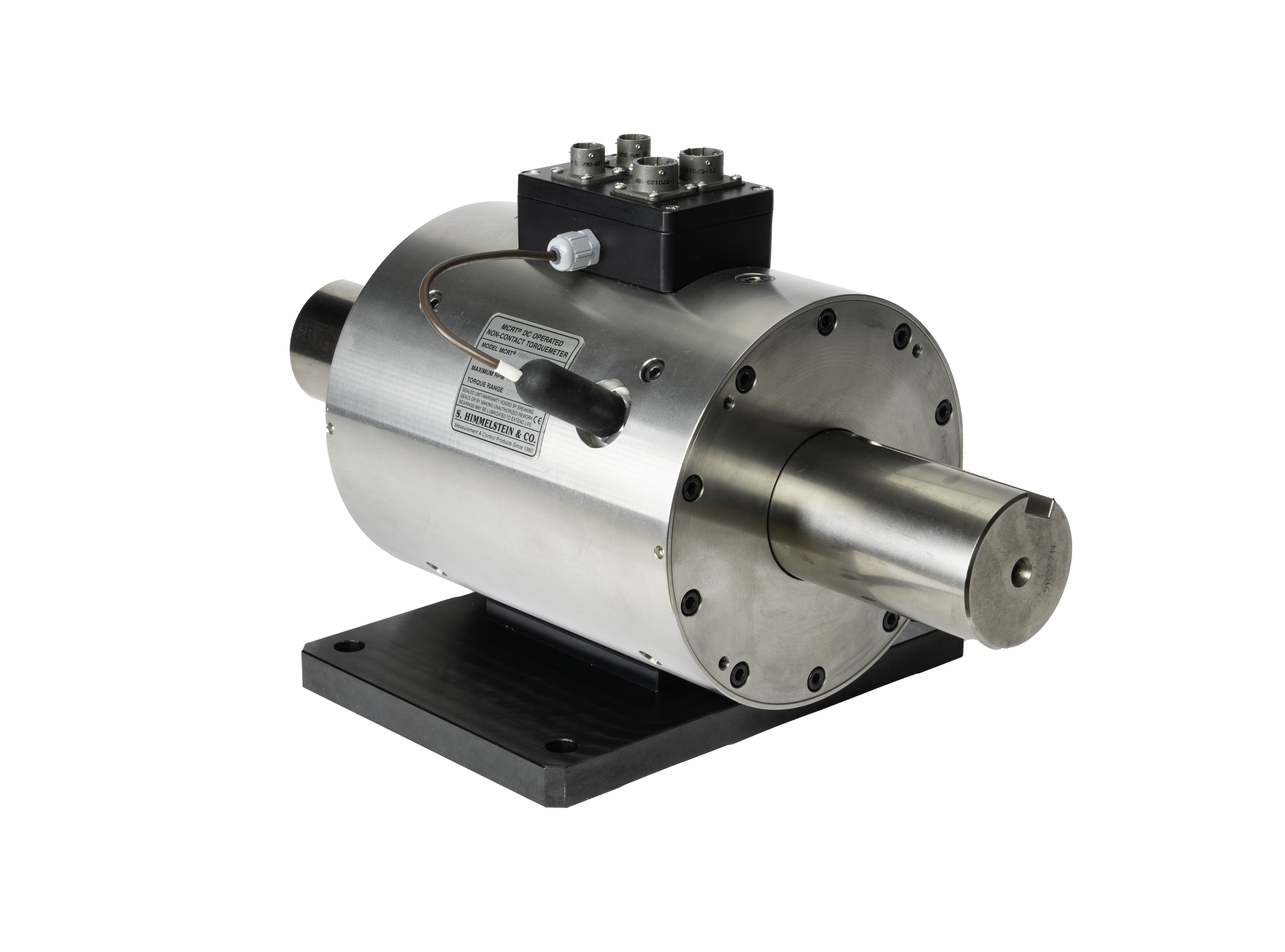

All our contactless torque transducers utilize highly accurate, proven and reliable strain gauges as the basis for the measurement. The latest, most accurate Himmelstein torquemeters — both rotating and non-rotating (reaction) types — are digitally based. The signal from rotating types is digitized on the rotor and transmitted as digital data to the stator, where analog and frequency (model dependent) signals are created and produced along with digital data. Each torque transducer employs true bi-directional rotor shunt calibration. All signal processing is microprocessor-based; most devices boast five microprocessors.

In-line rotating torquemeters with non-contact transfer of signal and excitation voltages, have become the method of choice for most torque and mechanical power measurement applications. Alloy steel sensing elements and built-in high immunity to noise and magnetic fields results in the most accurate and reliable sensors in the industry.

We offer several types of torque transducers to meet your measurement and application needs. For static torque measurement, choose a reaction torque sensor. For dynamic torque, select a rotary sensor. Our inventory offers a broad range of measurement capacities, overload ratings, accuracy classes and more. Get in touch with us today to learn more about what sets us apart among torque transducer manufacturers.

Himmelstein Model 700+ Series instruments are powerful, yet flexible one- or two-channel signal conditioners/displays. Our torque transducer instrumentation can be configured to interface with torque transducers, load cells, pulse output speed pickups and flow meters, voltage and current output transducers and more. High quality signal conditioning is a critical component in any sensor based measurement system for processing sensor output signals and providing clean, noise-free test data. Based on our decades of experience with strain gauge based sensors, we have optimized our signal conditioning for operation with all types of torque meters and other strain gauge transducers.

How does a torque transducer work?

Himmelstein torque transducers use highly accurate strain gauges to measure torque. Signals from rotating types are digitized on the rotor and transmitted to the stator, where they are processed into usable analog, frequency, and digital outputs.

What types of torque sensors does Himmelstein offer?

Himmelstein provides a variety of reaction and rotating sensors, including bearingless, shaft, flanged, splined, wheel, pulley, C-Face, and hollow types, to accommodate different measurement needs.

How are Himmelstein torque transducers calibrated?

All transducers are calibrated bi-directionally (CW and CCW) to their full-scale capacity in an ISO/IEC 17025:2017 accredited laboratory, ensuring accurate and traceable measurements.